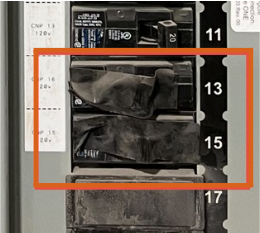

At EPSCO, we frequently encounter these “tape-out” scenarios, and it’s a critical issue we need to address head-on. While the immediate thought might be “it’s just temporary,” the implications are far-reaching, potentially leading to serious injury or even fatalities.

Why “Tape-Out” Fails the Safety Test

The core of the problem lies in the fundamental principles of energy isolation. According to NFPA 70E® 2024, Standard for Electrical Safety in the Workplace®, proper Lockout/Tagout (LOTO) procedures are paramount to ensuring worker safety during maintenance, servicing, or repair of electrical equipment. The objective of LOTO is to prevent the accidental or unintended energization, startup, or release of stored energy that could cause injury.

A piece of tape simply does not meet the stringent requirements for positive energy isolation. Here’s why:

- Lack of Physical Restraint: Tape offers no physical barrier to prevent a breaker from being inadvertently switched back to the “ON” position. A bump, an accidental brush, or even vibration can easily dislodge or break the tape, re-energizing the circuit without warning.

- Vulnerability to Mechanical Failure: Breakers, like any mechanical device, can fail. Internal mechanisms can wear, leading to an unexpected change in state, even if taped.

- No Positive Verification: A proper LOTO procedure involves verifying the absence of voltage after applying lockout devices. Tape provides no such mechanism for positive verification.

- Absence of Accountability: LOTO tags clearly identify who applied the lockout, the date, and why. This crucial information is entirely absent with a piece of tape, making accountability impossible and increasing the risk of miscommunication or premature energization.

- Non-Compliant with NFPA 70E: The final point is compliance. NFPA 70E explicitly outlines the requirements for effective energy control procedures, and taping a breaker simply does not satisfy these requirements. Ignoring these standards puts your workers and your organization at significant risk of regulatory violations and potential legal repercussions.

The EPSCO Recommendation: Embrace True Energy Isolation

The solution is clear and non-negotiable: Always use approved lockout devices and tags for electrical energy isolation. These devices are engineered to provide a robust physical barrier, preventing accidental energization and ensuring a safe working environment.

At EPSCO, we strongly advocate for:

- Comprehensive Training: Ensure your team is thoroughly trained on the principles and practical application of your company’s LOTO program, aligning with the latest NFPA 70E standards.

- Strict Adherence to Procedure: LOTO is not a suggestion; it’s a mandatory procedure. Foster a culture where LOTO is always followed, without exception or shortcut.

- Recognizing Hazards for What They Are: Treat temporary fixes like tape for what they truly are: unacceptable hazards. They create a false sense of security and undermine the very foundation of electrical safety.