What Should You Get out of an Arc Flash Study?

Arc Flash compliance– but what does this mean? Without an engineering background, it can be a challenge to understand all the regulations and cost benefits surrounding Arc Flash studies. Many of our EPSCO clients come to us knowing they have to meet code but not too much else. We make it a priority to help everyone understand the value and core principles of undertaking an Arc Flash study at their facility.

The objective of a comprehensive Arc Flash study should be to set up a safety program that everyone on your team regularly follows. Every facility has different tasks that need to be performed, equipment that’s used on the job, and employee responsibilities. An Arc Flash study takes those specific factors into account and then is used to build a custom safety program based on your work environment’s unique setup and needs.

If you don’t have a safety program in place already or if your program needs an update, it’s helpful to perform an electrical safety audit. It will assess your program and help you focus on where to make improvements, updates, and the gaps that need to be filled in.

To be compliant, an Arc Flash study should follow the requirements set out by the NFPA 70E.

It should use the Incident Energy calculation method and be performed by a licensed engineer. A complete study according to code will generate a full report and detailed electrical schematics.

Often, inexperience can lead to confusing the PPE Category Method with a compliant Arc Flash study.

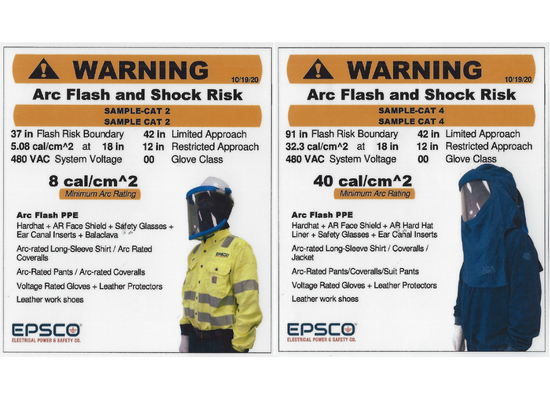

A true Arc Flash study utilizes Incident Energy calculations based on data collected from an entire system. An electrical model of the entire facility is built with the help of advanced engineering software and then used to create safety labels for each specific piece of equipment to designate the proper type of PPE that should be worn when working on that gear.

The PPE Category Method (sometimes called tables) only offers an estimate and range of potential arc flash levels. Because the PPE Category Method is non-specific, it must be performed before each time work is done.

The labels are the key to compliance.

Starting in 2015, NFPA 70E regulations state that labels can only be generated from an Arc Flash study that reports Incident Energy Levels in calories/cm2 and does not permit labels to be created via the PPE Category Method.

Starting in 2015, NFPA 70E regulations state that labels can only be generated from an Arc Flash study that reports Incident Energy Levels in calories/cm2 and does not permit labels to be created via the PPE Category Method.

Once your Arc Flash study is complete–

it needs to be maintained with any updates to your facility and compliance renewal every five years. If you continually work with a company specializing in Arc Flash safety like EPSCO, it can be easier and more efficient to maintain the study down the road. Changing vendors usually requires starting a new study from scratch because obtaining data requires sign-off from the original engineer.

At EPSCO, electrical safety is our number one goal for our clients. If you have questions about an Arc Flash study or how to comply with the NFPA 70E, get in touch with one of our electrical safety pros HERE.

Don’t forget to subscribe to our blog to get notified when we publish a new article!